TALC in engineering polymers

There are plenty of plastic applications where engineering polymers are commonly used.

Such polymer matrixes are normally characterized by high mechanical and thermal properties and, in general, are modified with functional fillers to boost their strong points.

Functional fillers, such as IMI Fabi talc, can provide significant improvements maximizing the service temperature of the polymer. Because of its lamellar structure, IMI Fabi talc behaves as a reinforcer, without negatively affecting either dimensional stability or aesthetics. For this reason, IMI Fabi talc can be also used as glass fiber extender for improved dimensional stability, warpage reduction and better aesthetics.

When very fine talc grades are used, a significant benefit in impact resistance is also recorded. Because of its high mineral pureness and chemical inertness, IMI Fabi talc is suitable for most engineering polymer requirements.

Such polymer matrixes are normally characterized by high mechanical and thermal properties and, in general, are modified with functional fillers to boost their strong points.

Functional fillers, such as IMI Fabi talc, can provide significant improvements maximizing the service temperature of the polymer. Because of its lamellar structure, IMI Fabi talc behaves as a reinforcer, without negatively affecting either dimensional stability or aesthetics. For this reason, IMI Fabi talc can be also used as glass fiber extender for improved dimensional stability, warpage reduction and better aesthetics.

When very fine talc grades are used, a significant benefit in impact resistance is also recorded. Because of its high mineral pureness and chemical inertness, IMI Fabi talc is suitable for most engineering polymer requirements.

Over the years, IMI Fabi has developed a specific range of products designed for high end applications

IMI Fabi Talc grades for engeenering polymers

According to the set of properties required by the final application, there is a specific IMI Fabi talc grade able to fulfill each requirement.

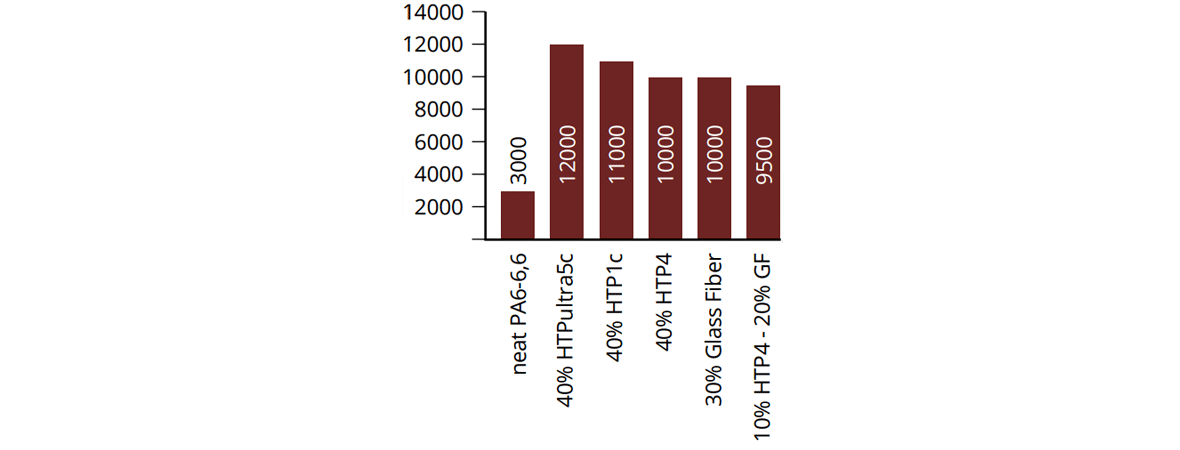

For extremely high demanding applications, HTPultra grades are the perfect answer. Thanks both to their high lamellarity and their fineness, HTPultra grades can provide a superior stiffness-to-impact balance, offering, at the same time, low molding shrinkage in combination with superior dimensional stability. The use of such grades in combination with glass fibers leads to improving the flow properties during molding, with minimal or no loss in both stiffness and impact. HTPultra grades offer the best CLTE properties too.

HTP and BT grades offer a broad range of propertiestogether with extremely high brightness andpureness. Because of the high lamellarity of thesegrades, it is possible to achieve very good mechanicalproperties in combination with excellent aesthetics.

When color is unimportant, for example in dark/black colored items, GT/CH grades can play astrategic role; because of their interesting cost-toperformanceratio, they are the perfect modifierin all applications where increased stiffness is asrelevant as the cost.IMI Fabi micronized talc grades are generally offeredin compacted form for improved bulk handling,low dust generation and increased achievablethroughput, but they are also available in powderform to satisfy any type of handling requirement.

For extremely high demanding applications, HTPultra grades are the perfect answer. Thanks both to their high lamellarity and their fineness, HTPultra grades can provide a superior stiffness-to-impact balance, offering, at the same time, low molding shrinkage in combination with superior dimensional stability. The use of such grades in combination with glass fibers leads to improving the flow properties during molding, with minimal or no loss in both stiffness and impact. HTPultra grades offer the best CLTE properties too.

HTP and BT grades offer a broad range of propertiestogether with extremely high brightness andpureness. Because of the high lamellarity of thesegrades, it is possible to achieve very good mechanicalproperties in combination with excellent aesthetics.

When color is unimportant, for example in dark/black colored items, GT/CH grades can play astrategic role; because of their interesting cost-toperformanceratio, they are the perfect modifierin all applications where increased stiffness is asrelevant as the cost.IMI Fabi micronized talc grades are generally offeredin compacted form for improved bulk handling,low dust generation and increased achievablethroughput, but they are also available in powderform to satisfy any type of handling requirement.

| IMI Fabi talc grade |

Example of application |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GT4410 | PA6/PA66 modification | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BT2207 HTP4 | PA6/PA66 reinforcement PBT reinforcement |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| CH2 | Modification of Polyolefins for pipe applications | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| HTP1c | PP reinforcement | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| HTP ultra5c | FR ABS/PC modification | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tensile modulus [MPa]

Customer support

IMI Fabi has an application laboratory dedicated to polymer applications. Our team is keen to assist polymer manufacturers in selecting the most suitable talc grades relevant for their final applications.