TALC for plastic recycling

Over the years, IMI Fabi has developed a specific range of products for the modification of recycled plastics

Day after day, plastic recycling is becoming more and more important both for environmental and for economic reasons.

Very often, recycled materials are used to lower the cost of the final item and requested to provide high performance.

Talc is a perfect modifier for recycled material since it can boost mechanical properties minimizing the impact on formula cost. Because of the high lamellarity, talc is able to provide highstiffness, fast processing cycles and low molding shrinkage. Talc provides excellent dimensional stability as well.

Talc is the right modifier for high end recycled products, but it also fits for disposable applications, where cost becomes the main property.

Talc is perfect for polyolefin modification, but it can be used for many other recycled polymers, where high rigidity is requested.

Very often, recycled materials are used to lower the cost of the final item and requested to provide high performance.

Talc is a perfect modifier for recycled material since it can boost mechanical properties minimizing the impact on formula cost. Because of the high lamellarity, talc is able to provide highstiffness, fast processing cycles and low molding shrinkage. Talc provides excellent dimensional stability as well.

Talc is the right modifier for high end recycled products, but it also fits for disposable applications, where cost becomes the main property.

Talc is perfect for polyolefin modification, but it can be used for many other recycled polymers, where high rigidity is requested.

IMI Fabi Talc grades for plastic recycling

IMI Fabi has developed a specific range of products suitable for plastic recycling. In black/dark applications they are characterized by an exceptional cost-to-performance balance.

IMI Fabi talc grades for plastic recycling are characterized by consistent composition, precise particle size distribution and long term availability.

Because of the lamellar shape of particles, IMI Fabi talc provides:

• High stiffness

• Outstanding dimensional stability

• Low molding shrinkage

• Optimum cycle times

IMI Fabi talc is perfect for recycled polyolefins used for injection molding and extrusion, but it is also suitable for all recycled polymers when high stiffness and good dimensional stability are required.

Because of the significant increment in stiffness, the usage of talc in plastic recycling represents a good opportunity for items down-gauging; in fact, the high achievable stiffness due to talc modification allows to reduce the thickness of molded or extruded items granting the original mechanical performances, butusing less material.

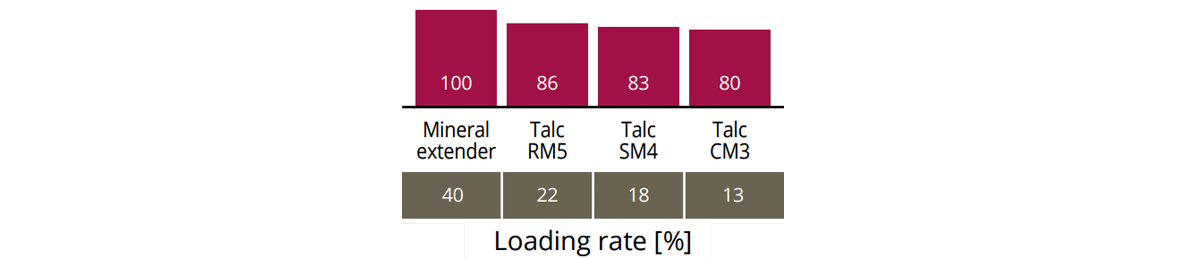

In comparison with mineral extenders, IMI Fabi talc provides a significant reduction of part weight when the same item rigidity is requested; in fact, thank sto the higher achievable rigidity, it is possible to lower the loading rate of talc granting same stiffness achievable with a standard mineral extender.

IMI Fabi talc grades for plastic recycling are characterized by consistent composition, precise particle size distribution and long term availability.

Because of the lamellar shape of particles, IMI Fabi talc provides:

• High stiffness

• Outstanding dimensional stability

• Low molding shrinkage

• Optimum cycle times

IMI Fabi talc is perfect for recycled polyolefins used for injection molding and extrusion, but it is also suitable for all recycled polymers when high stiffness and good dimensional stability are required.

Because of the significant increment in stiffness, the usage of talc in plastic recycling represents a good opportunity for items down-gauging; in fact, the high achievable stiffness due to talc modification allows to reduce the thickness of molded or extruded items granting the original mechanical performances, butusing less material.

In comparison with mineral extenders, IMI Fabi talc provides a significant reduction of part weight when the same item rigidity is requested; in fact, thank sto the higher achievable rigidity, it is possible to lower the loading rate of talc granting same stiffness achievable with a standard mineral extender.

| IMI Fabi talc grade | Example of application | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GT4410 | Disposable containers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| CH2 | Automotive applications Tiles for garden Industrial plallets |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BT2213 | Articles for building industry Automotive appplications |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

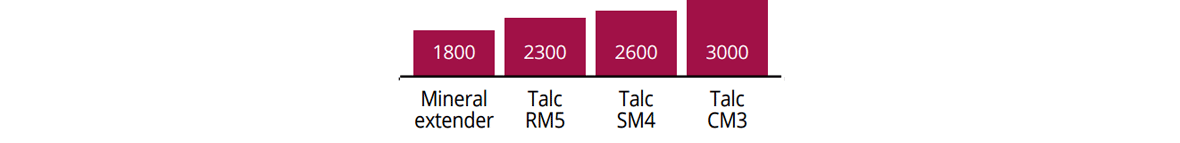

Recycled cPP@ 40% mineral filler

Tensile modulus [MPa]

Tensile modulus [MPa]

Part weight for same item rigidity [%]

Customer support

IMI Fabi has an application laboratory dedicated to polymer applications. Our team is keen to assist polymermanu facturers in selecting the most suitable talc grades relevant for their final applications.